shift89: using augmented reality to pass on industrial know-how

Training plays a key role in industry, given productivity requirements and recruitment challenges facing the sector. The start-up shift89, incubated at IMT Starter and present at VivaTech 2023, uses augmented reality to help industrial companies disseminate expertise and know-how, and highlight the value of jobs that are sometimes looked down on.

While there is much talk about the “industry of the future”, the sector is currently facing contemporary problems, starting with recruitment. According to an Insee study, two thirds of industrial companies experienced hiring problems in 2022, which was higher than in previous years.

Philippe Laforge and Emmanuel Bricard, co-founders of the start-up shift89, come from the world of industry and have faced this issue themselves. “At our previous company, we needed to increase our staff by 50% on a regular basis, due to the cyclical nature of the business,” says Philippe Laforge, “which represented a twofold challenge: finding the right talent and effectively training them to get them up to speed as quickly as possible. In industry, every second counts!”

This is a typical situation for industrial players, for whom training is crucial. The two colleagues, who were looking for a way to optimize the process, found a possible solution in 2016. “Microsoft was releasing its HoloLens headset,” says Emmanuel Bricard. “A full computer with transparent screens that can display holograms, which the user can interact with. Right away, we saw its potential for transferring know-how.” A few years later, the release of the HoloLens 2 model convinced the two associates to launch shift89.

Intuitive, permanently available training

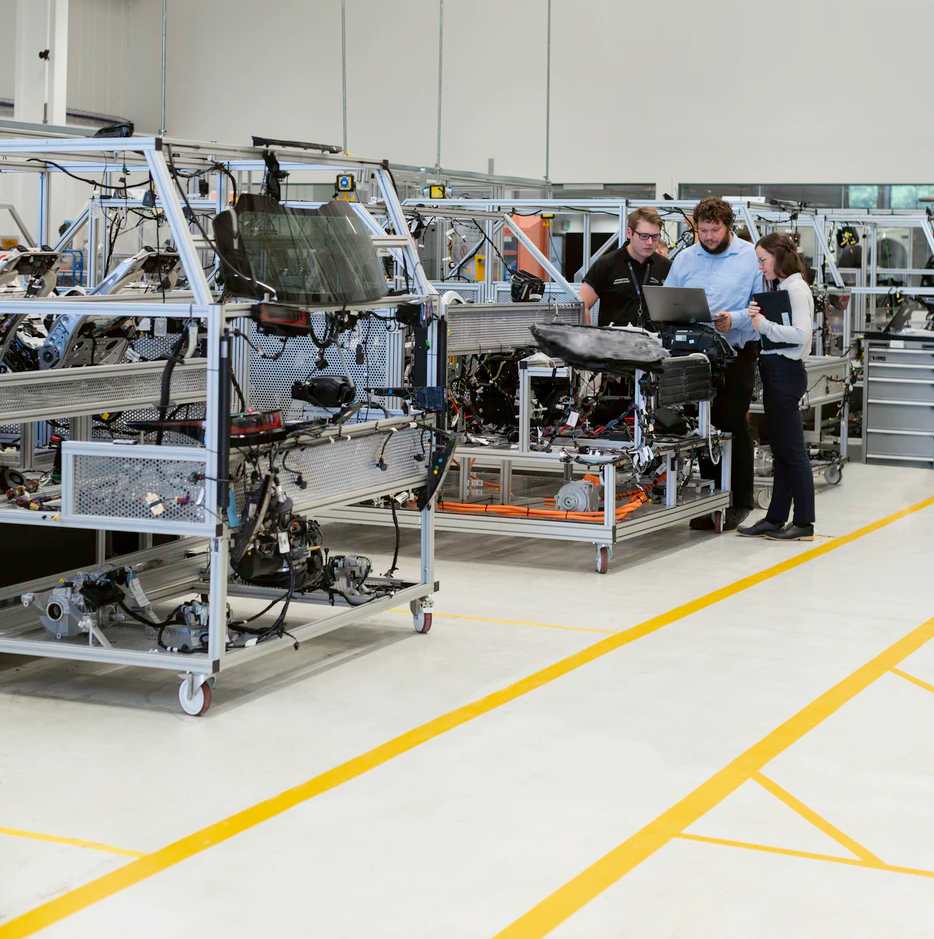

The start-up is currently incubated at IMT Starter (which brings together Telecom SudParis, Institut Mines-Telecom Business School, and ENSIIE). It offers software to easily create training for any manual job, using augmented reality. Industrial companies can therefore easily share their know-how with teams, based on an endless number of use cases: assembly workstation, machine maintenance, use of safety equipment etc. “We feel that extreme simplicity is crucial, both for the trainer and the employee to be trained,” says Bricard. “We know that a solution that’s too complicated would not actually be adopted in the field. Therefore, any employee can get started quickly with our tool.”

shift89 nevertheless supports its clients when they are getting started with the tool, helping them with the first real use cases for a day or so. The aim: share best practices for developing effective training, such as structuring content in a series of brief sequences – an educational approach that fosters understanding and memorization.

Once a training course has been created, any employee may complete it, using a HoloLens headset, and may repeat it as many times as they like. “That’s a real advantage, since you don’t have to get a group of employees together for a training session, or monopolize a trainer at several different times,” says Laforge. The expertise therefore remains permanently available, ready to be shared with the right people, at the right time. “Training is a company’s memory,” says Bricard. “In light of the many uncertainties weighing on their business, it’s essential for industrial companies to facilitate the dissemination of its know-how among its teams.”

Augmented reality or virtual reality?

To develop a solution tailored to its users, shift89 conducted a series of studies. Their objectives were to determine the best way to leverage augmented reality in an industrial setting, maximize its acceptability and identify the keys to effective training. The studies were carried out in collaboration with laboratories at Telecom SudParis, which has recognized expertise in augmented reality.

Using this technology was an obvious choice for the start-up. “With our tool, the trainer can add explanations in various formats: images, video, voice or text,” says Laforge. “Then, when employees complete the training, they are guided in their learning, with components displayed in the right place, on their real work station, while keeping their hands free.” This is a different kind of immersion to that of virtual reality, which requires recreating a 3D work environment for each job, and may also cause a feeling of discomfort called virtual reality sickness. Moreover, in a study conducted with Telecom SudParis, shift89 demonstrated the greater effectiveness of 2D training – by displaying holograms on an augmented reality headset – compared to 3D training.

A new way of looking at manual jobs

The start-up recently entered a new stage of commercial production and marketing, with its version released in February 2023, following the first successful tests. shift89 found that its solution helped teams save time, especially specialists who are in charge of training new employees. This leaves them more available to develop relationships with their new colleagues and provide further advice to those who need it.

In addition, shift89 helps make employees more versatile, “a topic that’s especially important to us,” says Bricard. “Since training is made easier, employees can learn a variety of skills, at different workstations. The company therefore increases its know-how and agility, as it has greater flexibility within its teams. But this also helps employees avoid routine, by changing stations more easily.” And it is not just a matter of mental well-being, since this diversity of work also helps reduce the risk of musculoskeletal disorders.

Moreover, in general, using an innovative solution like shift89 helps highlight the value of jobs that are looked down on at times. “A gradual shift is taking place in our societies,” says Bricard. “For decades, there was a kind of disdain for manual tasks, which were seen as inferior to intellectual work. But the Covid crisis upended this perception, by highlighting the importance of essential jobs, which everyone depends on to eat, receive care and have things delivered. Today, it’s more crucial than ever to highlight the value of this know-how.” shift89 plans to do its part, by using augmented reality-based training to convey a new image of manual jobs.

By Bastien Contreras.

Leave a Reply

Want to join the discussion?Feel free to contribute!