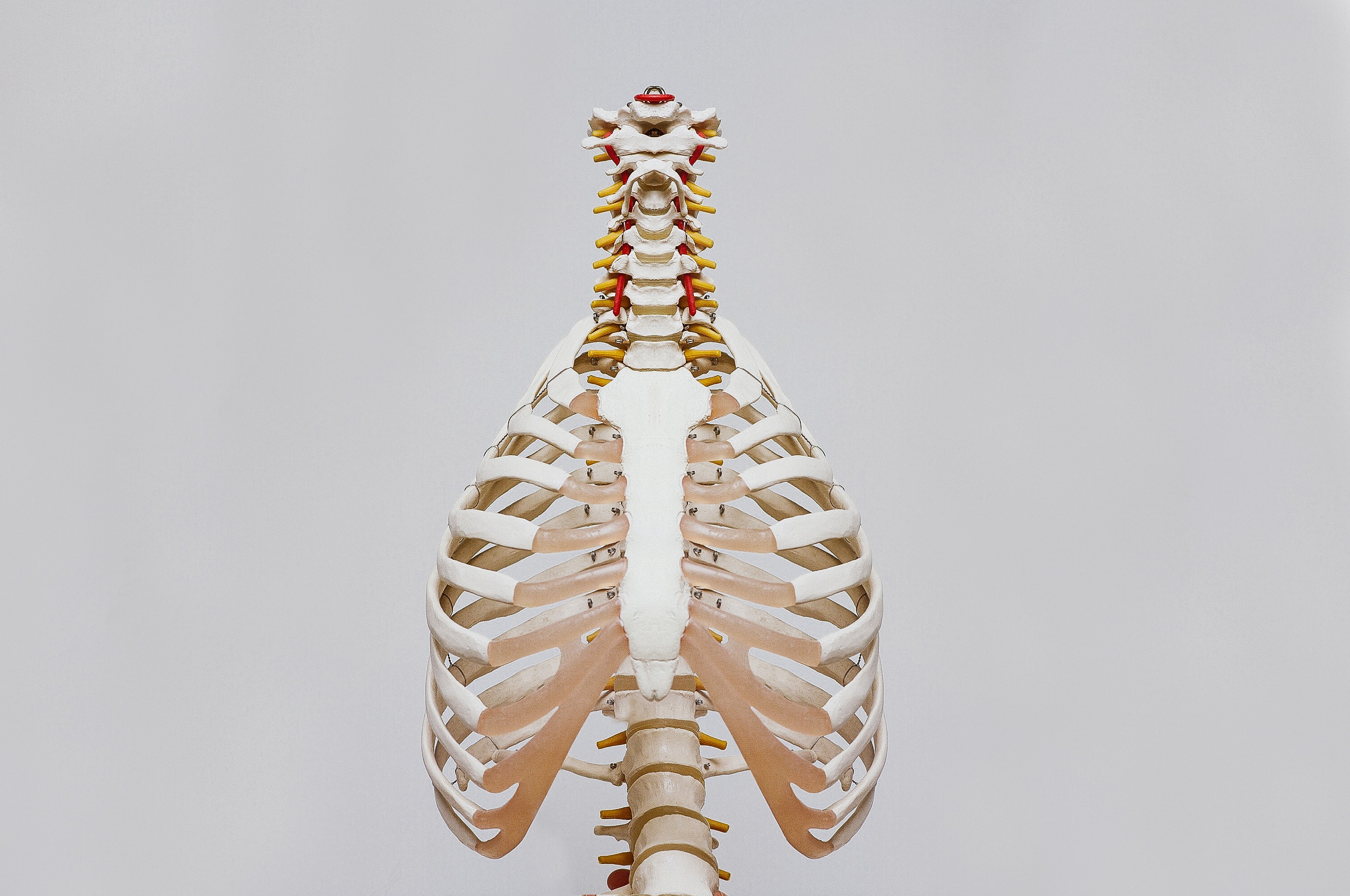

STREAM: Bone tissue model culture

The STREAM project, which Mikhaël Hadida is working on at Mines Saint-Étienne, aims to develop a controlled, carefully-managed bone tissue culture platform. This system would facilitate observation in order to study the mechanisms involved in bone tissue by reducing the costs and time required for research.

A culture system for bone tissue models in a controlled environment that allows for simplified observations: this is the aim of the STREAM project. Led by Mikhaël Hadida, a researcher at Mines Saint-Étienne, the STREAM research project (System for Bone Tissue Relevant Environment And Monitoring) aims to provide academic and industrial players with a useful tool for developing simplified, standardized and automated bone tissue models.

This in vitro culture system seeks to provide an innovative alternative to avoid animal testing in bone biology research. It is designed for laboratories, but could also be used to validate a medical system for pharmaceutical compounds or medical devices. This could pave the way for advances in research on osteoporosis, for example, or help make living bone grafts for regenerative medicine applications.

“The structure allows us to control the mechanical parameters of the system,” explains Mikhaël Hadida. It will be possible to control the culture conditions “and measure cell activity by collecting key data in real time.” The ability to control the mechanical environment of this type of culture has never before been reported in scientific literature. This would allow for better reproducibility between experiments, a key issue in research, while lowering costs and reducing the time required for research.

Little-understood mechanisms

One of the problems with current systems is the lack of a controlled environment. If the environment is not homogenous, it is difficult to draw conclusions from the experiments. “In research, we still don’t have a clear understanding of what is involved in mechanical stress on bone tissue,” explains Mikhaël Hadida.

Current systems are generally designed using biomimicry based on demineralized bone. They remain very close to the human system and therefore imply better performance. “But it’s also a very complex system that is not possible to control or manage,” says the researcher.

There may be other phenomena involved, which in turn could affect the results observed. It is difficult to determine whether the parameters used have a real impact on the culture, or if other mechanisms the researchers are not aware of come into play. New collagen-based structures have also been developed, but they are still based on these highly complex systems. “It’s an attempt to find a shortcut – seeking performance before the foundations of these mechanisms are properly understood,” he adds.

The Bone Stream system

Mechanical stress in bones is not directly related to wear and tear, but bone cells react to mechanical stimuli that can damage bone tissue. Our bones are made up of a solid matrix and pore fluid. Walking or running leads to micro-stimulations – micro-compressions on this fluid – which create “currents” that stimulate the mechanisms involved.

“At the Centre for Biomedical and Healthcare Engineering, David Marchat can make us tailor-made culture scaffolds, which are perforated,” explains Mikhaël Hadida. The system the research team is working on is perfused to reproduce these fluid movements in the culture medium and obtain conditions similar to those of real life. “So we have a good combination in terms of the culture chamber and the culture medium to ensure that all the bone cells have a homogenous scaffold.”

Read more on I’MTech: Bone implants to stimulate bone regeneration

This homogeneity is essential to control the system and understand what impacts the culture, so as to be certain that it is indeed the mechanisms used that are responsible and not another variable the researchers are not aware of. Parameters tested include, for instance, fluid flow speed and what is known as shear stress. If you put pressure on a cube by moving your hand down its side, you apply a force parallel to the surface: this is shear stress.

Direct observation

“This system would also offer a major advantage for making observations,” says Mikhaël Hadida. “Current culture systems are destructive. In order to observe the culture they must be interrupted,” he explains. The culture scaffold must first be taken out of its environment. Then cell markers must be injected and it must be cut into very fine slices so that they can be examined under a microscope. It can also be ground up to analyze the DNA.

If you wish to study the development of your culture, these destructive methods pose a major problem. “If you want to observe your culture on a given day, then two days later, then a week later, your needs increase with all these observations,” he says. This means culture scaffolds must be available for each observation, which requires a significant investment, in terms of time and costs.

“So we wanted to develop a platform that could observe the culture in real time,” says the researcher. Their culture scaffold is installed on the transparent inner face of the culture chamber. This extends into a viewing chamber to monitor its evolution with a microscope without disturbing the culture scaffold. “We also have sensors to study the evolution of cell activity,” he adds. “They monitor changes in the culture medium very closely and therefore keep track of how the cells develop.”

The goal is now to continue developing this platform to bring a culture tool to the market that stands out from those already available. “For example, we’re working on a project with the European Space Agency (ESA) on this topic,” says Mikhaël Hadida. The astronauts on board the International Space Station (ISS) are subjected to specific mechanical stress and present a phenomenon of accelerated aging of bone tissue upon their return. ESA is therefore actively involved in this research in order to better understand this phenomenon and find solutions.

By Tiphaine Claveau, for I’MTech

Leave a Reply

Want to join the discussion?Feel free to contribute!