Innovative approaches to recycling brominated plastics

Recovering untreated plastic materials and putting them back into the recycling loop through a decontamination line is the challenge of thesis research by Layla Gripon, a PhD student at IMT Lille Douai. These extraction methods contribute to a comprehensive approach to recovering plastic materials, in particular brominated plastics.

High consumption of electronic devices implies a significant amount of waste to be processed. While waste electrical and electronic equipment (WEEE) is often seen as a gold mine of silver and rare earths, plastic materials represent 18% of these deposits. This was equivalent to 143,000 tons in France in 2018 according to a report by Ademe (Ecological Transition Agency) published in 2019. But not all this plastic material is created equal. Some of it contains atoms of bromine – a chemical compound that is widely used in industrial flame retardants. These substances meet requirements for reducing flammability hazards in devices that may get hot while in use, such as computers or televisions. There’s just one problem: many of these substances are persistent organic pollutants (called POP). This means that they are molecules that can travel great distances without being transformed, and which are toxic to the environment and our health. The amount of these molecules contained in devices is therefore regulated in the design stage, as well as in the end-of-life processing stage. In 2019, the European Union set the threshold at which waste containing bromine can no longer be recycled at 2 grams per kilo. Beyond this limit, it is destroyed through incineration or used as fuel. But couldn’t it still be recycled, with the right processing? For her thesis co-supervised by researchers at IMT Lille Douai and The Alençon Institute of Plastics and Composites (ISPA), Layla Gripon has set out to identify a method for separating brominated flame retardants from plastics. “We seek to maximize recycling by limiting the loss of unrecoverable material, while complying with regulations,” says the PhD student.

Finding the right balance between extraction efficiency and respect for the environment

Approximately 13% of WEEE plastics are above the legal threshold for brominated flame retardants, which is equivalent to 17,500 tons in France. Samples tested in the laboratory reached a concentration of bromine up to 4 times higher than the legal threshold. In order to process them, Layla Gripon tested a number of methods that do not degrade the original plastic material. The first was highly efficient, removing 80% of the bromine. It was an extraction method used diethyl ether, an organic solvent. But since it uses a lot of solvent, it is not an environmentally-friendly solution. Another technique based on solvents is dissolution-precipitation. Through this technique, plastic is dissolved in the solvent, which retains the flame retardants. “In order to limit the environmental impact of this process, we subcontracted the German Fraunhofer Institute to carry out a test. Their patented process (CreaSolv) allows them to reuse the solvents. In the end, the bromine was no longer detected after processing and the environmental impact was reduced,” she explains.

In addition, a method that is more environmentally-friendly – but less efficient, for now – uses supercritical CO2, a green, non-toxic and non-flammable solvent. This process is already used in the agri-food industry, for example, to remove caffeine from coffee. In the supercritical state, carbon dioxide exists in an intermediate state between liquid and gas. To achieve this, the gas is heated and pressurized. In practice, the closed-loop system used by Layla Gripon is simple. Shredded plastic is placed inside an autoclave in which the supercritical fluid circulates continuously. When it leaves the autoclave, the recovered gas brings various additives with it, including a portion of the flame retardants.

To improve the yield of the second method, Layla Gripon planned to use a small amount of solvent. “The tests with ethanol improved the yield, with a rate of 44% of bromine removed, but this wasn’t enough,” says the PhD student. Other solvents could be considered in the future. “The supercritical CO2 method, on the other hand, works very well on the brominated flame retardant that is currently the most widely-used in industry (tetrabromobisphenol A – TBBPA),” she adds. But the most difficult brominated plastics to process are the ones that have been prohibited for a number of years. Although they are no longer available on the market, they are still accumulating as waste.

A large-scale approach to recovering recycled plastic

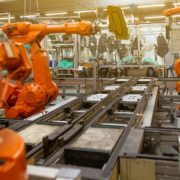

These promising processing techniques must still evolve to respond fully to the needs of the recycling industry. “If these two processes are selected for applications beyond the laboratory, their environmental impact will have to be minimized,” says the PhD student. Such methods could therefore be incorporated in the pre-processing stage before the mechanical recycling of WEEE plastics.

At the same time, manufacturers are interested in the benefits of this research initiated through the Ecocirnov1 Chair. “They’ve joined this project because the laws are changing quickly and their products must take into account the need to recover materials,” explains Éric Lafranche, a researcher who specializes in plastic materials at IMT Lille Douai and is Layla Gripon’s thesis supervisor. The objective of maximizing recycling is combined with an ambition to create new products tailored to the properties of the recycled materials.

Read more on I’MTech: A sorting algorithm to improve plastic recycling

“Recycling today is different than it was 10 years ago. Before, we sought to recover the material, reuse it with similar properties for an application identical to its original use. But the recycled product loses some of its properties. We have to find new applications to optimize its use,” says Éric Lafranche. For example, French industrial group Legrand, which specializes in electrical installations and information networks, seeks to use recycled plastic materials in its electrical protection products. In collaboration with researchers from IMT Lille Douai, the company has implemented a multilayer injection system based on recovered materials and higher-grade raw materials on the surface. This offers new opportunities for applications for recycled plastics – as long as their end-of-life processing is optimized.

By Anaïs Culot.

1 Circular economy and recycling chair created in 2015, bringing together IMT Lille Douai, and the Alençon Institute of Plastics and Composites and Armines.

Leave a Reply

Want to join the discussion?Feel free to contribute!