In search of forgotten cements

Out of the 4 billion tons of cement produced every year, the overwhelming majority is Portland cement. Invented over 200 years ago in France by Louis Vicat — then patented by Englishman Joseph Aspdin —Portland is a star in the world of building materials. Its almost unparalleled durability has allowed it to outperform its competitors, so much so that the synthesis methods and other cement formulations used in the 19th and early 20th centuries have since been forgotten. Yet, buildings constructed with these cements still stand today, and cannot be restored using Portland, which has become a monopolistic cement. In a quest to retrieve this lost technical expertise, Vincent Thiéry, a researcher at IMT Lille Douai, has launched the Cassis[1] project. In the following interview, he presents his research at the border between history and materials.

How can we explain that the cement industry is now dominated by a single product: Portland cement?

Vincent Thiery: Cement as we know it today was invented in 1817 by a young bridge engineer: Louis Vicat. He needed a material that had high mechanical strength, which would set and have strong durability under water, in order to build the Souillac bridge over the Dordogne river. He therefore developed a cement based on limestone and clay fired at 1,500°C, which would later be patented by an Englishman, Joseph Aspdin, under the name Portland Cement in 1824. The performance of Portland cement gradually made it the leading cement. In 1856, the first French industrial cement plant to produce Portland cement opened in Boulogne-sur-Mer. By the early 20th century, the global market was already dominated by this cement.

What has become of the other cements that coexisted with Portland cement between its invention and its becoming the sole standard cement?

VT: Some of these other cements still exist today. One such example is Prompt cement, which is also called Roman cement — its ochre color reminded its inventor of Roman buildings. It’s an aesthetic restoration cement invented in 1796 by Englishman James Parker. It’s starting to gain popularity again today since it emits less CO2 into the atmosphere and can be mixed with plant fibers to make more environmentally-friendly cements. But it’s one of the few cements that still exist along with Portland cement. The majority of the other cements stopped being produced altogether as of the late 19th or early 20th centuries.

Have these cements always had the same formulation as they do today?

VT: No, they evolved over the course of the second half of the 19th century and were gradually modified. For example, the earliest Portland cements, known as “meso-Portland cements,” were rich in aluminum. There was a wider range of components at that time than there is today. These cements can still be found across France, in railway structures or old abandoned bridges. Although they are there, right before our eyes, these cements are little-known. We don’t know their exact formulation or the processes used to produce them. This is the aim of the CASSIS project – to recover this knowledge of old cements. The Boulogne-sur-Mer region in which we’ll be working should provide us with many examples of buildings made with these old cements, since it was where cement started its industrial rise in France. In the Marseille region, for example, research similar to that which we plan to conduct was carried out by the concrete division of the French Historic Monument Research Laboratory (LRMH), one of our partners for the CASSIS project. This research helped trace the history of many “local” cements.

How do you go about finding these cements?

VT: The LRMH laboratory is part of the Ministry of Culture. It directly contacts town halls and private individuals who own buildings known to be made with old concretes. This work combines history and archeology since we also look for archival documents to provide information about the old buildings, then we visit the site to make observations. Certain advertising documents from the period, which boast about the structures, can be very helpful. In the 1920s, for example, cement manufacturer Lafarge (which has since become LafargeHolcim) published a catalogue describing the uses of some of its cements, supported by photos and recommendations.

Once a structure has been identified as incorporating forgotten cements, how do you go back in time to deduce the composition and processes used?

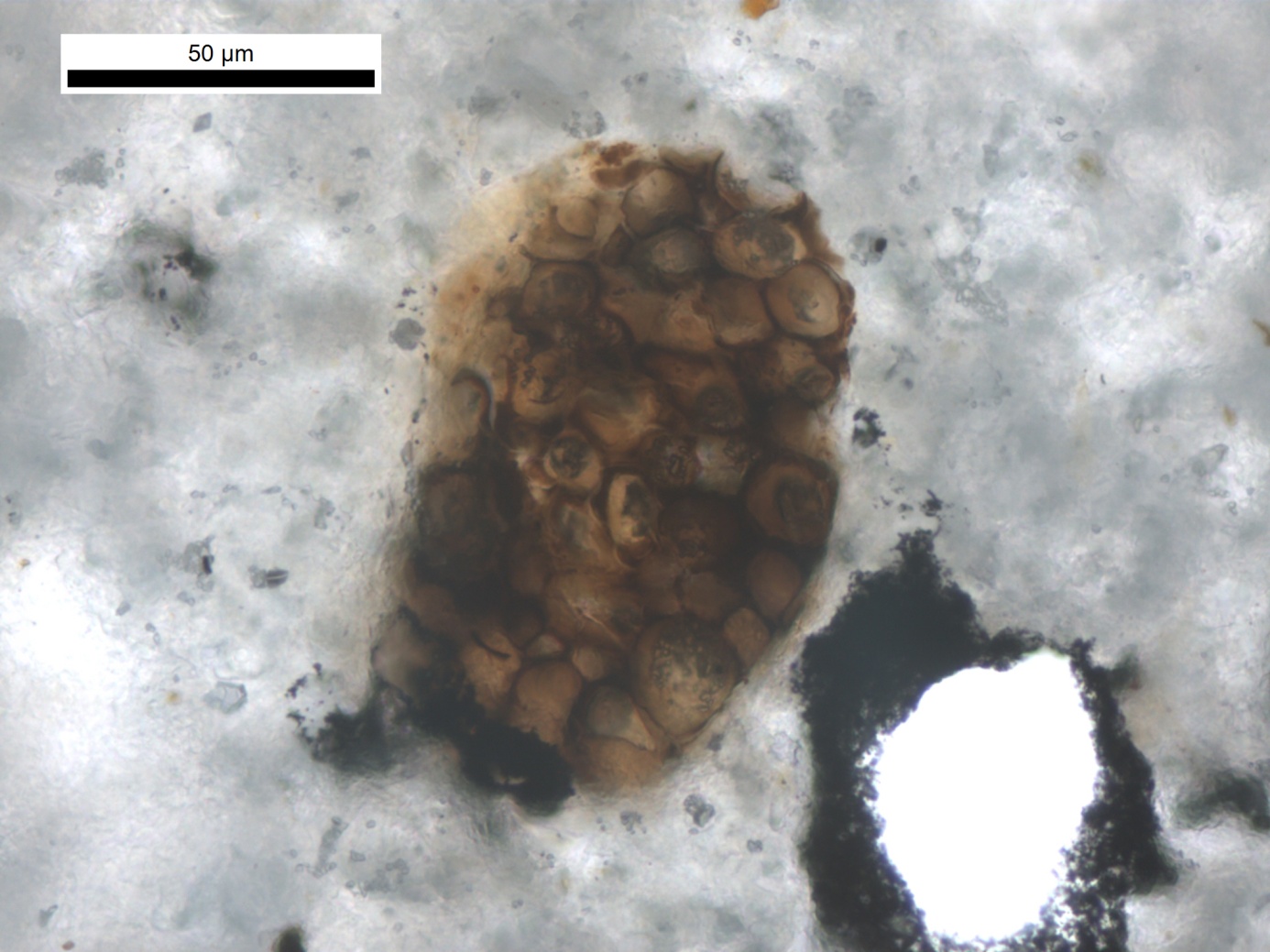

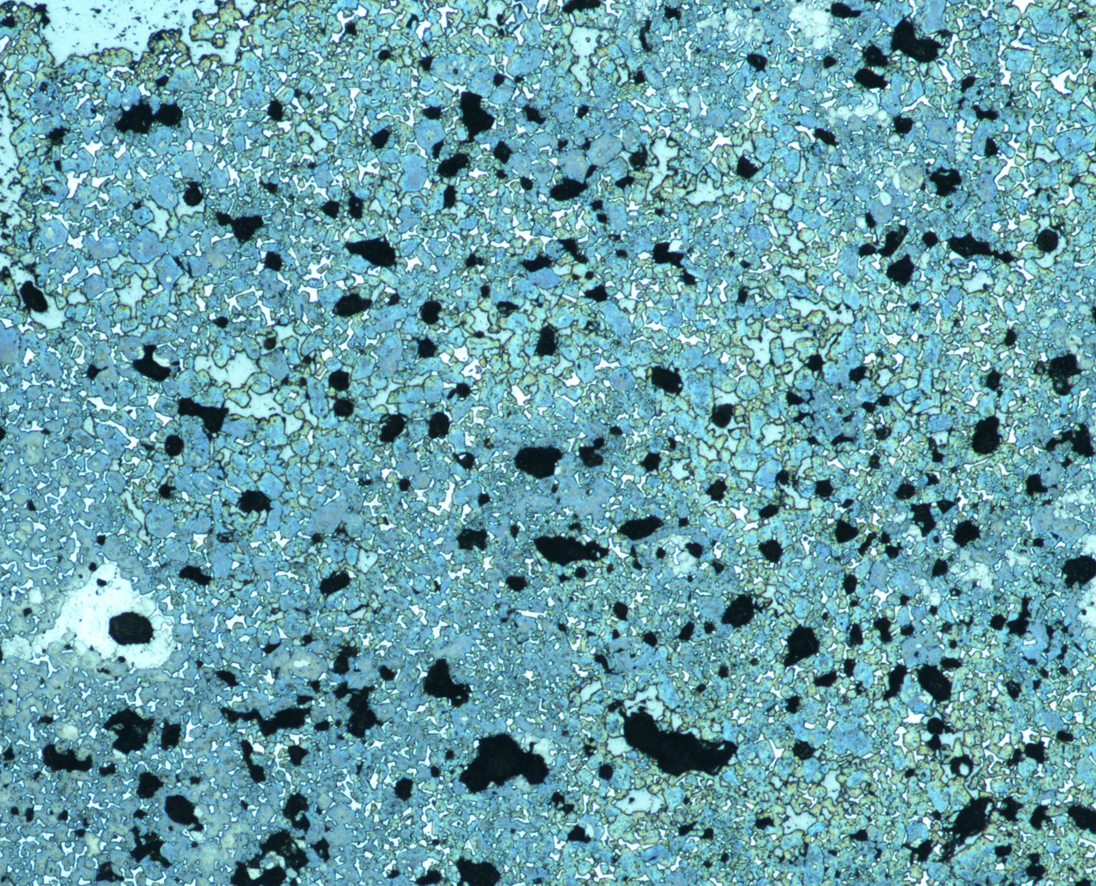

VT: It ‘s a matter of studying the microstructure of the material. We set up an array of analyses using rather conventional techniques in the field of mineralogy: optical or scanning electron microscope, Raman spectroscopy, X-ray diffraction etc. This allows us to detect mineralogical changes that appear during the firing of clay and limestone. This study provides us with a great deal of information: how the material was fired, at what temperature and for how long, as well as whether the clay and limestone were ground finely before firing. Certain characteristics of the microstructure can only be observed if the temperature has exceeded a certain level, or if the cement was fired very quickly. As part of the CASSIS project, we’ll also be using nuclear magnetic resonance since the hydrates— which form when the cement sets — are poorly crystallized.

It is this, along with other types of microstructural evidence within a cement paste, whether mortar or concrete, that makes it possible to gain valuable insight into the nature of the cement used. It is a relic of a speck of non-hydrated cement in a mortar from the early 1880s. To make these observations, samples are prepared in thin sections (30 micrometers thick) in order to be studied with an optical microscope. The compilation of observations and analyses of these samples provides information about the nature of the raw mix (the mix before firing) used to make the cement, its fuel and firing conditions: the same approach will be used for the Cassis project.

Do you have a way of verifying if your deductions are correct?

VT: Once we’ve deduced the possible scenarios for the mix and process used to obtain a cement, we plan to carry out tests to verify our hypotheses. For the project, we will try to resynthesize the forgotten cements using the information we have identified. We even hope to equip ourselves with a vertical cast-iron kiln to reproduce firing from the period, which is marked by the irregularities of the firing conditions in the kiln. By comparing the cement obtained through these experiments with the cement in the structures we’ve identified, we can verify our hypotheses.

Why are you trying to recover the composition of these old cements? What is the point of this work since Portland cement is considered to be the best?

VT: First of all, there’s the historical value: this research allows us to recover a forgotten technical culture. We don’t know much about the shift from Roman cement to Portland cement in the industry of the period. By studying the other cements that existed at the time of this shift, we may be able to better understand how builders gradually transitioned from one to the other. Furthermore, this research may be of interest to current industry players. Restoration work on structures built with forgotten cements is no easy matter: the new cement to be applied must first be found to be compatible with the old cement to ensure strong durability. So from a cultural heritage perspective, it’s important to be able to produce small quantities of cement adapted to specific restoration work.

[1] The CASSIS project is funded by the I-SITE Foundation (Initiatives-Science – Innovation –Territories– Economy) at the University of Lille Nord Europe. It brings together IMT Lille Douai, the French Historic Monument Research Laboratory (LRMH) of the Ministry of Culture, Centrale Lille, the Polytechnic University of Hauts-de-France, and the technical association of the hydraulic binders industry.

Leave a Reply

Want to join the discussion?Feel free to contribute!