Five years ago, Benjamin Dupas launched his company, Wallace Technologies, on his own. Today, he is supported by Pauline Chanin Lambert, who serves as CEO. Together, they attended Jean Zay High School in Thiers before reuniting in 2022 on a research contract at Mines Saint-Étienne, where the start-up is incubated.

Originally, this project was born out of a need to break free from the energy constraints of our time. But the path to energy transition is fraught with many challenges, including that of storing enough energy. “Electricity production is not equal to consumption at any given moment, and with the production of renewable energies, it is increasingly necessary to store this energy so that it can be delivered when needed,” says Pauline Chanin Lambert.

Renewable energies are becoming increasingly prevalent in our society, but they still struggle to sustainably supply large energy networks. “We depend on wind and sun to produce them, so to ensure the stability of the network, we need to store this energy,” she points out. It is against this backdrop that Wallace Technologies has developed a highly efficient storage solution.

The thermal battery, a system-solution

The start-up’s innovation lies in the use of its particularly efficient thermal battery. The battery works like a “Carnot” model, meaning that electricity is stored in the form of heat at temperatures that can reach 650°C. This thermal energy can then be converted back into electricity. Unlike traditional lithium batteries, Wallace Technologies’ battery is based on molten aluminum.

It is made up of three elements, three technological building blocks which, when combined, enable energy to be stored: an electricity-heat converter, a heat transfer loop, and an aluminum reservoir. The recovered electricity first passes through the converter, which is powered by a Stirling engine. Inside, the electricity is converted into heat. The transfer loop then carries the heat to the tank, melting the aluminum and transforming it into a liquid state. To recover the electricity in the form of heat, the aluminum is cooled to return to its solid state, and the converter then changes the heat back into electricity.

The heat exchanger connected to the transfer loop is particularly important, as it is this mechanisme that allows the thermal fluids to be exchanged inside the system. In the exchanger, fluids of different temperatures circulate and cross paths but never meet directly. “It’s a design that resembles the staircase at Chambord,” explains Pauline Chanin Lambert. The lower the heat loss, the higher the energy efficiency of the battery.

Highly compact technology for efficiency

Wallace Technologies stands out by striving to push the cursor as high as possible in terms of efficiency. After all, thermal batteries are all about efficiency. “Storing 1 kWh to get ten times less out of it isn’t really worth it,” emphasizes Pauline Chanin Lambert. Most traditional “Carnot” batteries offer low efficiency, meaning they can only restore a portion of the stored energy. The thermal batteries developed by Wallace Technologies achieve an efficiency rating of between 65 and 80%. “This is why our heat exchanger is essential in our battery, because it is what allows us to achieve high efficiency,” explains the engineer.

The creation of a highly compact, high-performance heat exchanger is made possible by the 3D printing technology developed by the start-up, with the help of Mines Saint-Étienne. The walls inside the exchanger are between 200 and 300 microns thick. “These extremely thin walls agglomerated into a small space offer a very high exchange surface area,” explains the researcher. Thanks to this system, it is possible to obtain 3,000 square meters of exchange surface area per cubic meter, three times more than in traditional heat exchangers. Or, conversely, to obtain a high-density exchanger that is three times more compact, with the same efficiency. This high density, coupled with the precise arrangement of the materials, optimizes the exchange of flows within the system.

Moving forward, despite constraints

For the moment, the first battery developed by Wallace Technologies offers a total of 7.5 kWh of usable energy. By way of comparison, the energy required to cover a 100-kilometre journey in an electric car is between 13 and 20 kWh, depending on the vehicle model. The start-up’s goal is to push the performance envelope even further, particularly in the industrial sector, but the technical hurdles will take time to overcome.

“The current 7.5 kWh storage solution requires 60 kilograms of aluminum. For a 1 mWh solution, 27 tons of aluminum would be needed, which is not the same thing!” points out Pauline Chanin Lambert. This energy challenge goes hand in hand with another need, which Wallace Technologie is seeking to satisfy: enabling manufacturers to store energy efficiently. Renewable energy players are interested in the capacity of the system developed by the start-up to store their electricity. But they are not the only ones: any industrial producer of energy, whether renewable or even nuclear, could indeed need to store electricity.

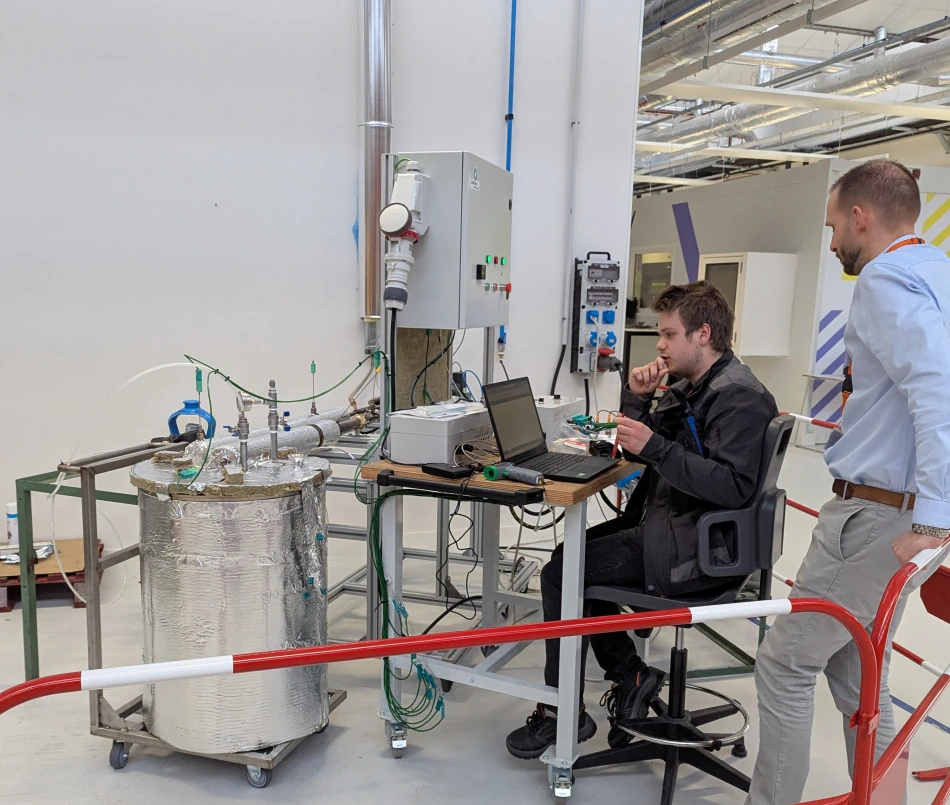

To develop its systems on an industrial scale, the Clermont-Ferrand-based structure can count on the support of various organizations, including Mines Saint-Étienne, where the start-up has been incubated since 2022. Last April, a thesis was launched to enable the scaling up of larger heat exchangers, which would therefore have a tenfold increase in capacity.

Mines Saint-Étienne also provides the equipment needed to develop the various projects undertaken by the start-up. “The combination of know-how and equipment is really important to us; it’s a very dynamic ecosystem,” asserts Pauline Chanin Lambert. After completing an initial round of fundraising in September 2024 and opening its R&D center in Saint-Étienne, Wallace Technologies has all the keys in hand for its development: warm up the carburetor, this is just the beginning.